". ." (xllx)

". ." (xllx)

05/23/2018 at 10:30 ē Filed to: properly fixed

3

3

15

15

". ." (xllx)

". ." (xllx)

05/23/2018 at 10:30 ē Filed to: properly fixed |  3 3

|  15 15 |

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> . .

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> . .

05/23/2018 at 10:34 |

|

RamblinRover Luxury-Yacht

> . .

RamblinRover Luxury-Yacht

> . .

05/23/2018 at 10:41 |

|

Apart from the fact that it might actually be weaker after the effect of the welds weakening the metal, what I love about this is that rebar is a total crapshoot in terms of material properties. This rebar could be more randomly high-carbon recycled, and STRONK LIKE BOOL except brittle, or it could be the steel equivalent of Laffy Taffy. Thereís no way to be sure.

facw

> . .

facw

> . .

05/23/2018 at 10:45 |

|

I mean, this one is by far the best youíve posted. Itís not at all pretty, and itís already rusty, but it seems entirely possible it could hit a bump (maybe more than one!) without immediately breaking apart?

SilentButNotReallyDeadly...killed by G/O Media

> . .

SilentButNotReallyDeadly...killed by G/O Media

> . .

05/23/2018 at 10:47 |

|

I see no duct tape. Itís still broken.

. .

> SilentButNotReallyDeadly...killed by G/O Media

. .

> SilentButNotReallyDeadly...killed by G/O Media

05/23/2018 at 10:47 |

|

Fair

RamblinRover Luxury-Yacht

> . .

RamblinRover Luxury-Yacht

> . .

05/23/2018 at 10:49 |

|

Further questions: is that squeeze bulb something stock, or some other kind of rigging thatís totally horrifying? Is it some kind of thing to re-prime the engine, and does that mean that thatís a fuel line running right by where they were welding?

. .

> RamblinRover Luxury-Yacht

. .

> RamblinRover Luxury-Yacht

05/23/2018 at 10:50 |

|

Iíd assume thatís for bleeding the fuel system on a diesel if it gets ran out of fuel.

benjrblant

> RamblinRover Luxury-Yacht

benjrblant

> RamblinRover Luxury-Yacht

05/23/2018 at 10:51 |

|

Letís also briefly discuss the difficulty in welding 16ga sheet to a 3/4" rebar.

RamblinRover Luxury-Yacht

> . .

RamblinRover Luxury-Yacht

> . .

05/23/2018 at 10:53 |

|

Kind of what I was thinking. So, diesel level weld fire hazard, not gas, but still terrible. Benzes have a dinky little push pump on the injection pump.

RamblinRover Luxury-Yacht

> benjrblant

RamblinRover Luxury-Yacht

> benjrblant

05/23/2018 at 10:55 |

|

Well, to be fair, if they got it up to temp with a torch first and spent about a minute cooling it down under contr... PFFT. BWAHAHAHA

Also, I think your ď16GAĒ is optimistic. 20, sure, 18 maaaaybe.

RamblinRover Luxury-Yacht

> facw

RamblinRover Luxury-Yacht

> facw

05/23/2018 at 11:07 |

|

It could probably go another 100,000 miles under the right conditions. Some attention to detail, and some care was taken, just not very informed care.

CalzoneGolem

> SilentButNotReallyDeadly...killed by G/O Media

CalzoneGolem

> SilentButNotReallyDeadly...killed by G/O Media

05/23/2018 at 11:13 |

|

Duck tape never rusts.

Stapleface

> . .

Stapleface

> . .

05/23/2018 at 11:19 |

|

I canít even figure out why the rebar is there. What is that even doing?

Decay buys too many beaters

> . .

Decay buys too many beaters

> . .

05/23/2018 at 12:15 |

|

Whenever I see you post a picture of a shock tower, I know I shouldnít click. Yet I click anyway.

RamblinRover Luxury-Yacht

> Stapleface

RamblinRover Luxury-Yacht

> Stapleface

05/23/2018 at 12:21 |

|

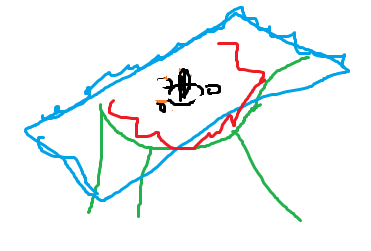

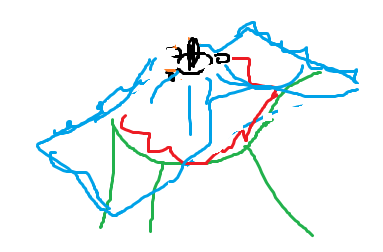

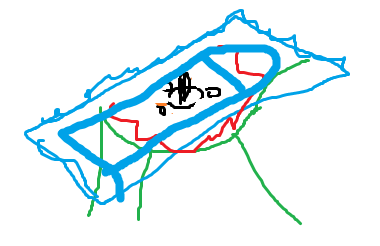

The original metal most likely had ribs for strength. Like this:

Being in a little cap at the top of the shock tower. The metal that has been added has no such ribs. Itís like this:

The original ďcapĒ to the shock tower is gone, so itís just a flat piece of thin sheet dropped on top and welded to the fender liner and heater box.

This presents a problem. Not only is the new metal much broader than the original, itís not tied to the shock tower in the same way, nor is it ribbed for extra strength. continual force will bulge it upward, like this:

The answer to this *correctly identified* problem was to make sure that the overall replacement was strong enough to not bulge in the middle and rip out - to brace the center of the repair area to the edges where it was welded, and where there was some strength. Like this:

The rebar is a truss of sorts to stiffen the sheet. The whole thing is ingenious, itís just also a bad idea. Why?

Because the places where the rebar is welded to the sheet arenít all that strong, and they weaken the sheet. Worst case, the sheet will flex between where itís welded to the rebar and where itís welded to the body.

(Bends, rips, distortion in orange).

So there you have it. What they were trying to do, and why not to do it, as presented in MSPaint.